Although we use machines as much as possible even for one off assemblies, yet we cannot avoid that for some boards, manual soldering is necessary. Manual soldering is not a task but an art!

Layout A (with pagination)

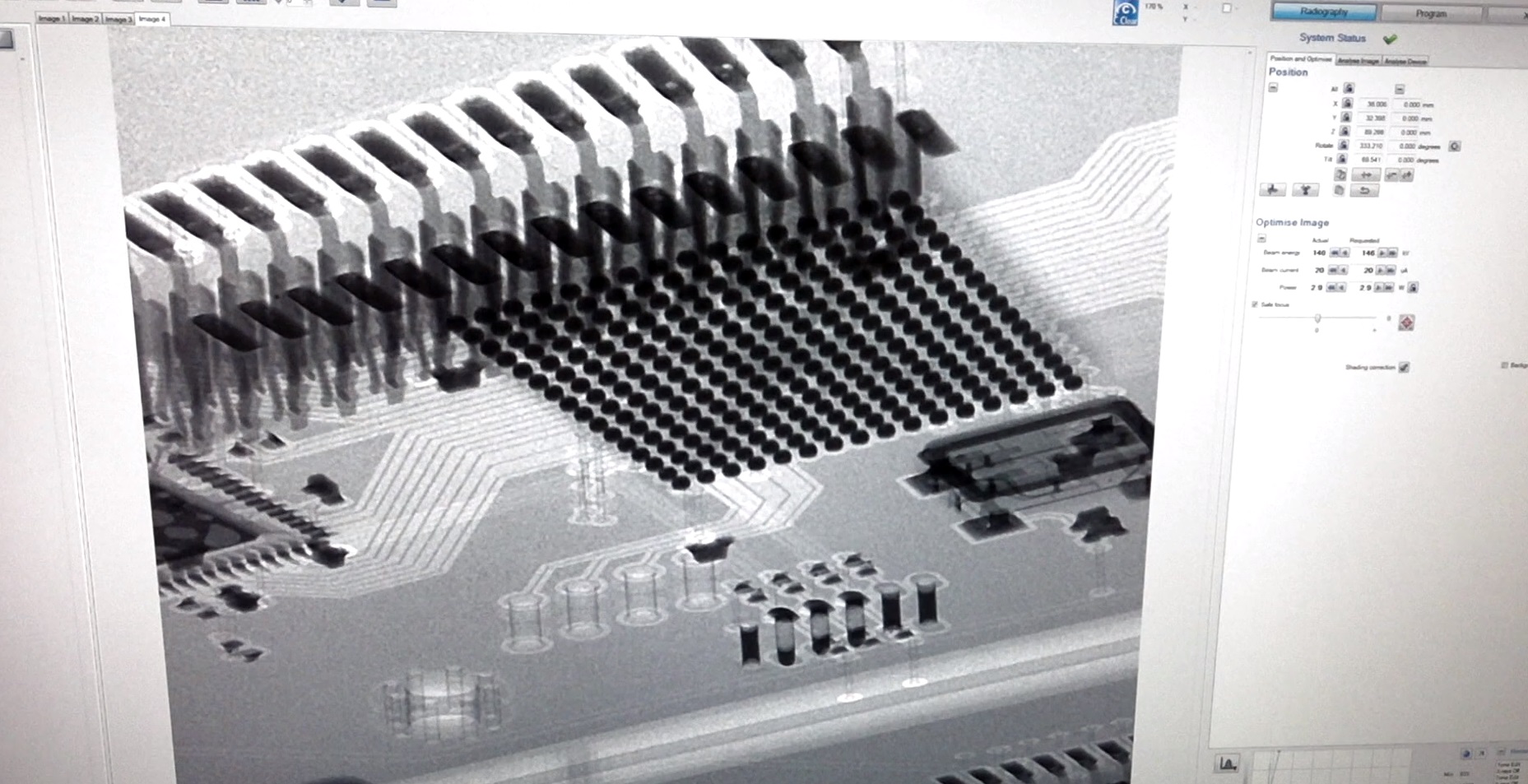

X-Ray inspection is a very useful technique to monitor the quality of our assembly process, especially for components where it is impossible to visually inspects the solder joints as these sit under the components body. For small batches it may also be used to check complex shapes of...

PCB Assembly: Reflow Soldering

After Pick & Place and inspection the board is moved into a massive reflow oven. Size matters here as the number of reflow zones defines the accuracy with which we can control the reflow soldering process.

Before any production, PCB or Assembly can start, a detailed Design For Manufacturing check is required. We check all component related specs against the PCB layout and report back any issue to the PCB team before they make the PCB production data ready. Thus to achieve right first time...

Starting from a prepared dataset, ready PCB’s, stencils and components mounted in feeders, we will now create proper instructions for the Pick & Place machines.