Although we use machines as much as possible even for one off assemblies, yet we cannot avoid that for some boards, manual soldering is necessary. Manual soldering is...

Recently published

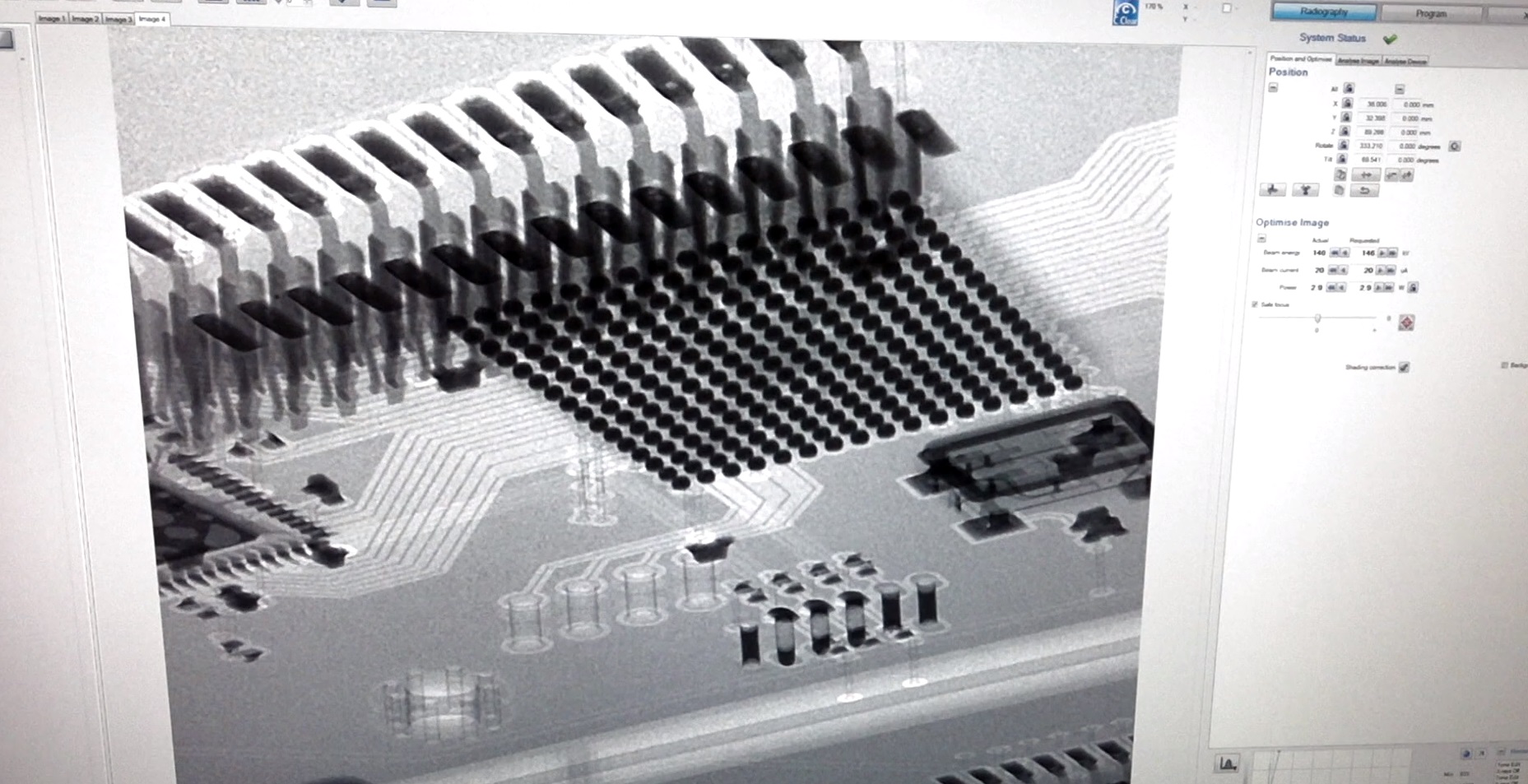

X-Ray inspection is a very useful technique to monitor the quality of our assembly process, especially for components where it is impossible to visually inspects the...

PCB Assembly: Reflow Soldering

After Pick & Place and inspection the board is moved into a massive reflow oven. Size matters here as the number of reflow zones defines the accuracy with which we...

Before any production, PCB or Assembly can start, a detailed Design For Manufacturing check is required. We check all component related specs against the PCB layout and...

Starting from a prepared dataset, ready PCB’s, stencils and components mounted in feeders, we will now create proper instructions for the Pick & Place machines.